Lombard Architectural Precast Products Company

LEARN MORE about lappcoProudly Serving Chicago & Surrounding Areas

LEARN MORE about lappcoDiscover LAPPCO'S Services

View our servicesWe've Been Busy, View Some of Our Projects

View ProjectsABOUT US

A leader in precast concrete

Since our beginning in the 1960’s Lombard Architectural Precast Products Company (LAPPCO) has developed a reputation for producing precast concrete on-time and on-budget without compromising service or quality. LAPPCO’s team of engineers and precast experts are among the most highly respected in the industry. Many owners and architects consult with our precast staff in the earliest stages of planning to maximum design possibilities and cost efficiencies. You will experience a higher level of professionalism, performance and value when you select Lombard Architectural Precast Products Company.

ABOUT US

A Leader in Precast Concrete

Since our inception in the 1960s, Lombard Architectural Precast Products Company (LAPPCO) has built a strong reputation for designing & fabricating precast concrete projects on-time and within budget, all while upholding exceptional standards of service and quality. The LAPPCO team, comprised of skilled engineers and precast experts, is widely recognized as among the most respected in the industry. Owners and architects across the Midwest choose to collaborate with our precast staff during the preliminary stages of project planning to leverage maximum design possibilities and cost efficiencies. When you choose LAPPCO, you can expect the highest level of professionalism, performance, and value in the industry.

Advantages of Precast Concrete

Design

- Versatility; endless variety of colors, shapes, textures, and patterns.

- Quality; produced in controlled environment with strict quality control standards

Functional

- Fire, storm, and blast resistant

- Environmentally friendly & energy efficient

- Accelerated schedule with minimal site disturbance

Economical

- Long life cycle

- Incorporates or simulates other more expensive materials

- Sustainable with minimal up-keep

Advantages of Precast Concrete

Design

- Moldable into most any shape

- Endless variety of surface finishes and colors

Function

- Load bearing capability

- Energy efficient

- Durable, with low maintenance

- Environmentally friendly

Economy

- Lower overall project costs

- Installs quickly

- All weather construction possible

- Incorporates or simulates other more expensive material

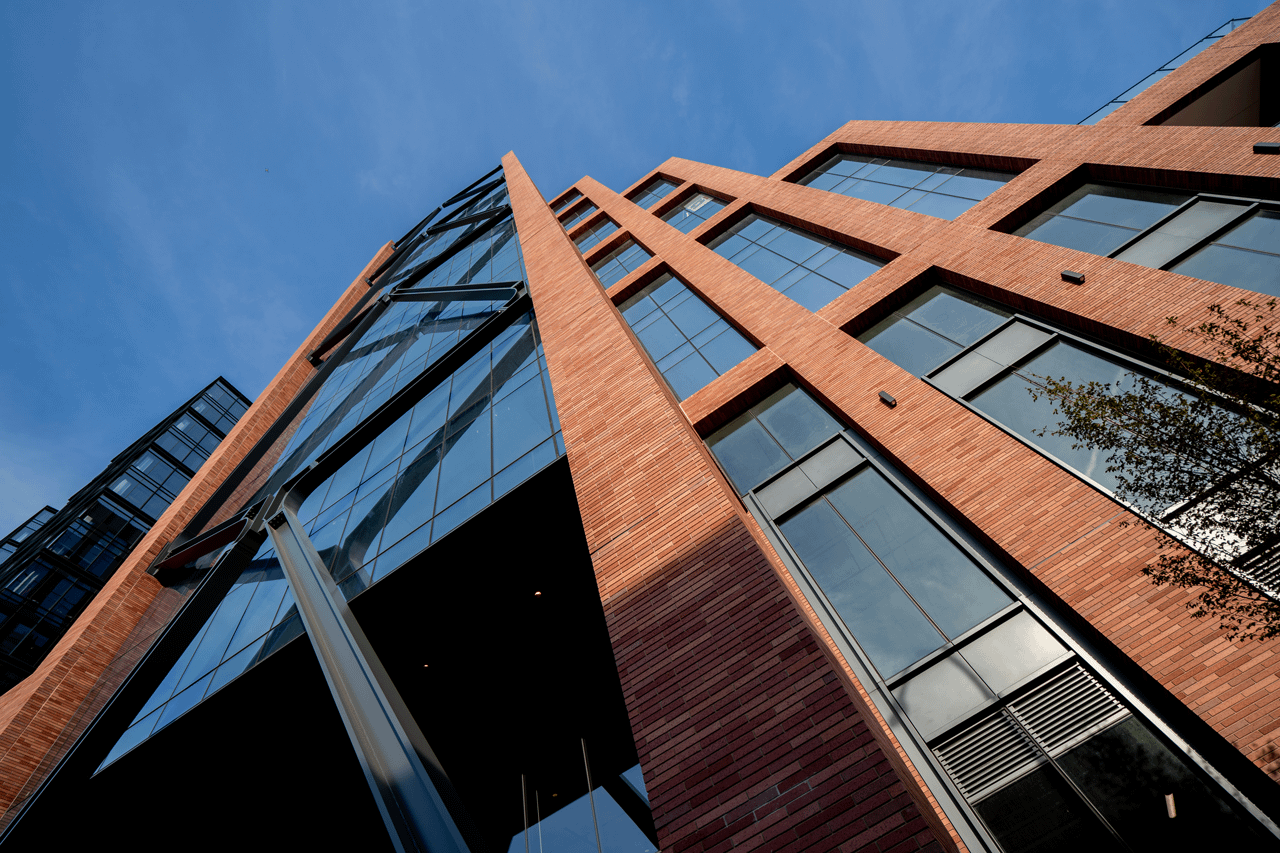

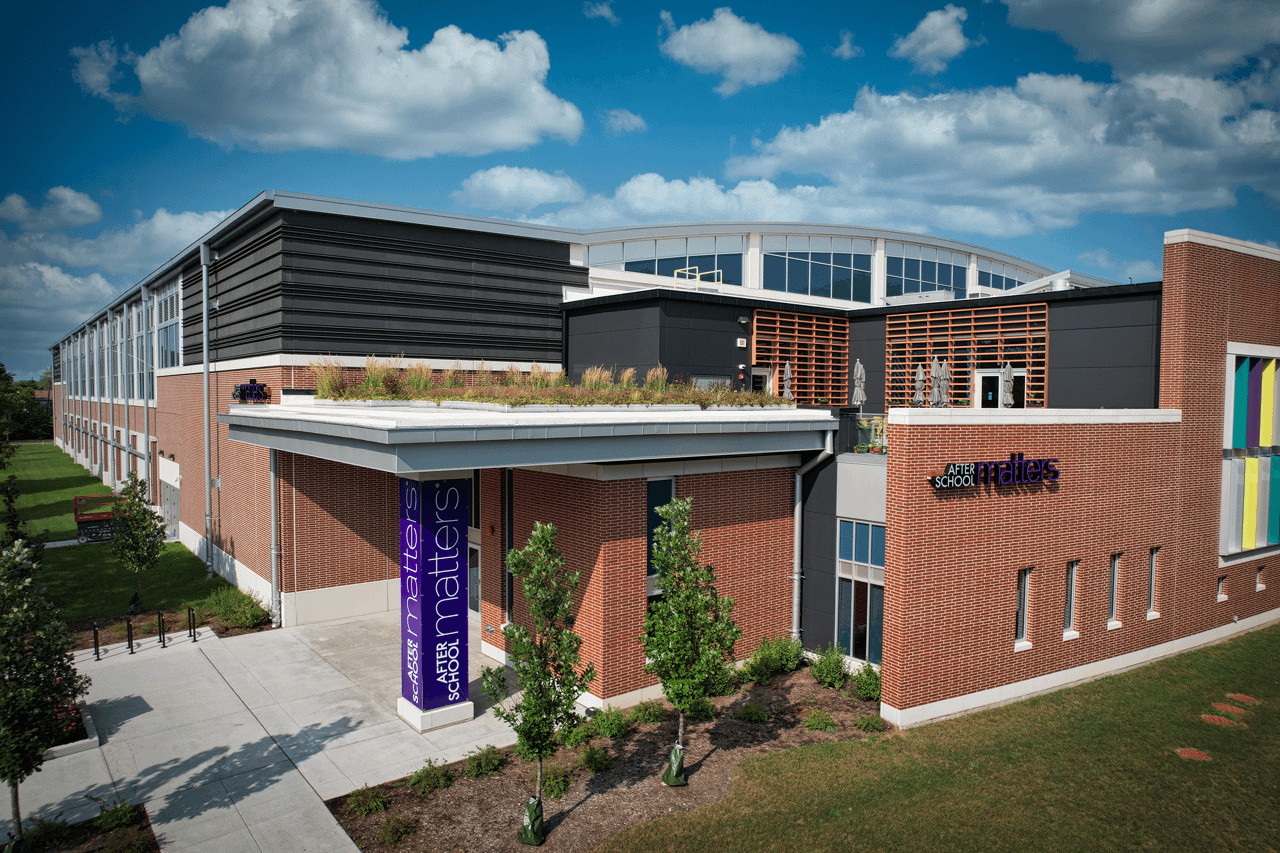

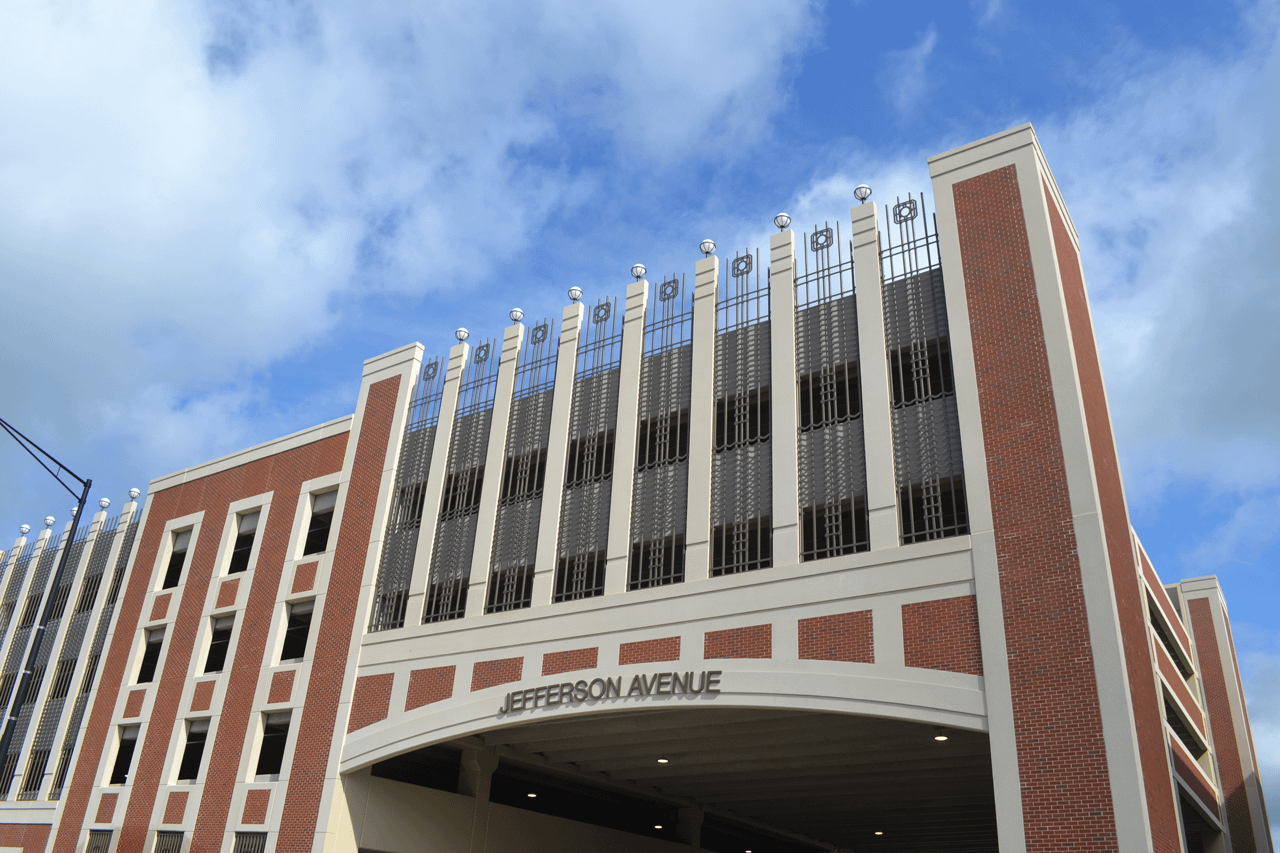

Our Products

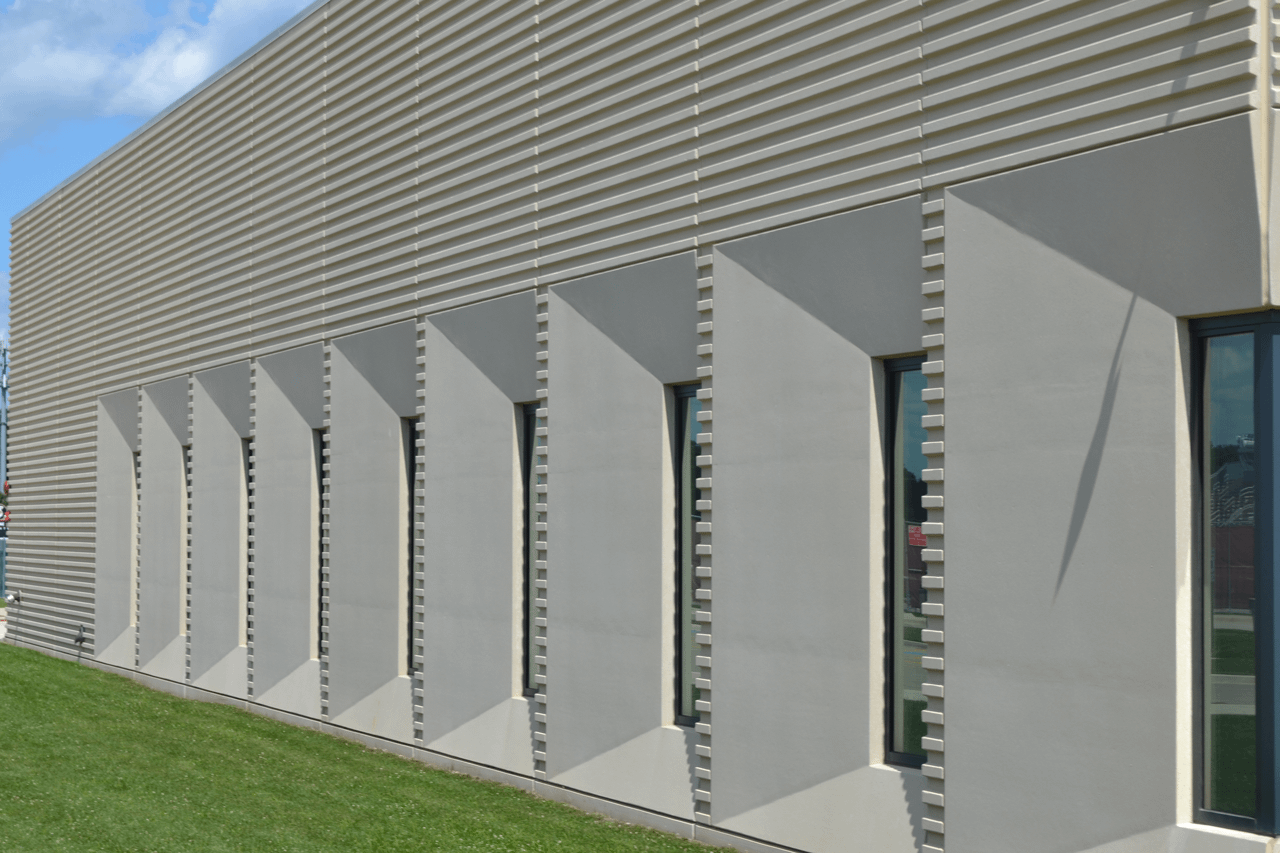

Architectural Wall Panels

Insulated & Non-Insulated, load bearing & non-load bearing, cladding

Cast-In Specialty Items

Cast-in thin brick, stone, or granite

Formliner

Ribs, waves, faux stone, shiplap, vertical & horizontal reveals

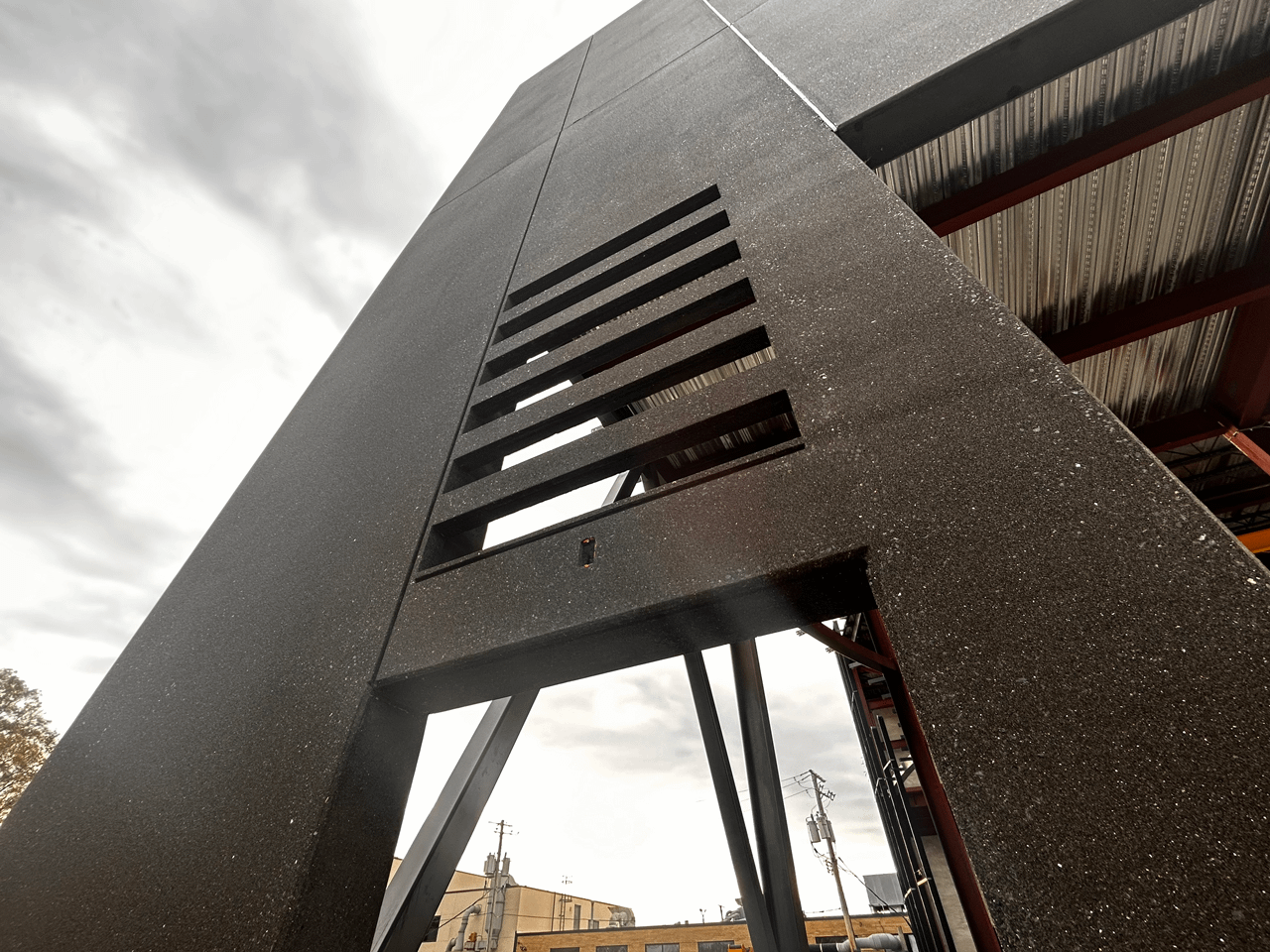

Custom Castings

Radiused, unique shapes, return corners, cornice, build-ups

Unique Colors / Finishes

Black, honey, limestone, acid etch, sandblast